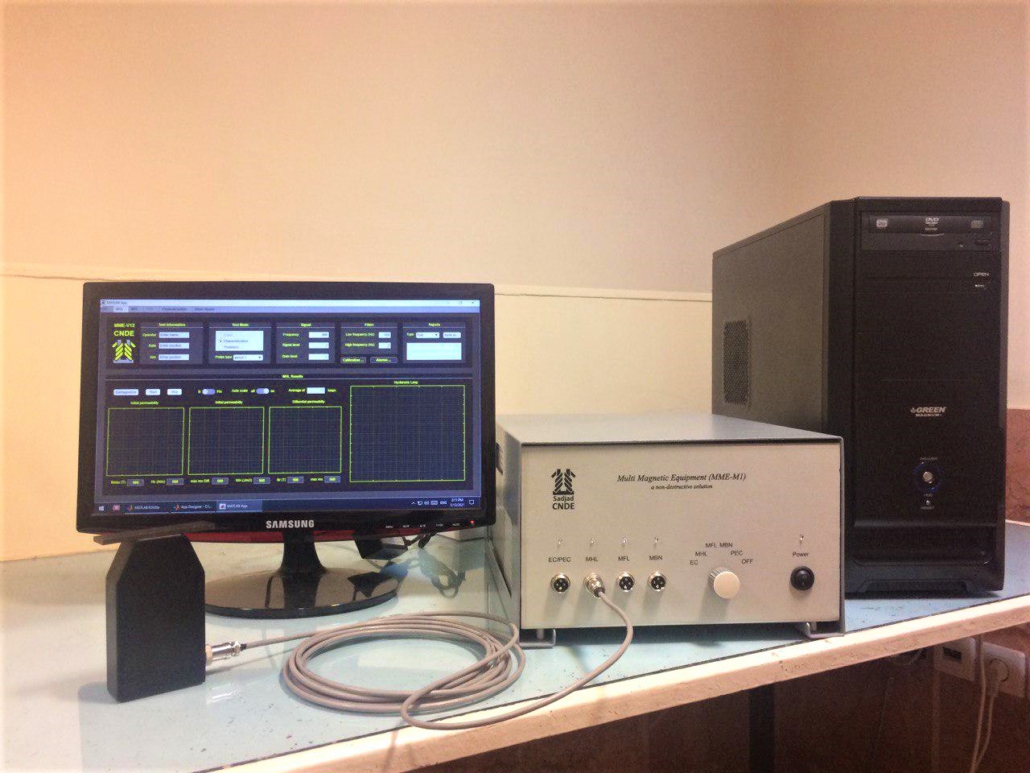

Multi Magnetic Nondestructive Equipment (MME)

MME is a device that could be easily used to characterize microstructure, physical and mechanical properties as well as discontinuities in the metal components such as steel, cast iron and Al alloys. A variety of probes can be connected to MMNE, including surface/needle/encircling eddy current (EC), Magnetic hysteresis loop (MHL), Magnetic Flux Leakage (MFL) and Magnetic Barkhausen Noise (MBN) probes.

The specific applications of MME include …

- characterization of microstructural changes in steels and cast-iron parts,

- determination of mechanical properties,

- assessment of magnetic properties,

- determination of electrical conductivity,

- estimation of carbon content of mild carbon steels,

- sorting nonferrous alloys and

- determination of hardened layer depth obtained from carburizing, nitriding and induction hardening

The general applications of MME include …

- measurement of non-conductive coating thickness on conductive metal,

- detection of cracks and determination of their features and

- detection of thickness variation in pipelines.