https://sadjadcnde.com/wp-content/uploads/2021/06/r_5_210207120251.jpg

990

700

admin

https://sadjadcnde.com/wp-content/uploads/2021/01/photo_2021-01-03_05-27-30-300x93.png

admin2021-06-19 12:12:242021-07-19 10:33:56Being certified as the top article by Center for Non-Destructive Evaluation (CNDE) on the conference on “Recent Advances in Railway Engineering (ICRARE 2021)”

https://sadjadcnde.com/wp-content/uploads/2021/06/r_5_210207120251.jpg

990

700

admin

https://sadjadcnde.com/wp-content/uploads/2021/01/photo_2021-01-03_05-27-30-300x93.png

admin2021-06-19 12:12:242021-07-19 10:33:56Being certified as the top article by Center for Non-Destructive Evaluation (CNDE) on the conference on “Recent Advances in Railway Engineering (ICRARE 2021)”NDT&E

Inspecting defects in internal parts such as engine blade, bolts, screw holes, landing gear, wheels and aluminum skin, joint weld, etc

Inspecting oil and gas pipelines, floating/fixed platforms, drilling rigs, tanks, vessels and heat exchangers, etc

Inspecting common rail defects including side/vertical wears, corrugations, rolling contact fatigue (RCF) cracks, etc

Determining defects during the manufacturing processes such as rolling, forging, casting, powder metallurgy (finding, locating and sizing)

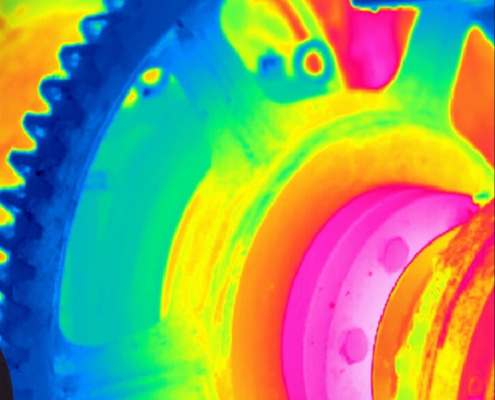

Inspecting composite material phases, friction stir welds, thickness variation due to the corrosion, fatigue cracking, etc

Controlling microstructure features (phase type, grain size, precipitation of secondary phases) and mechanical properties (strength, hardness, elongation) after heat treatment

NEWS

Products & Projects

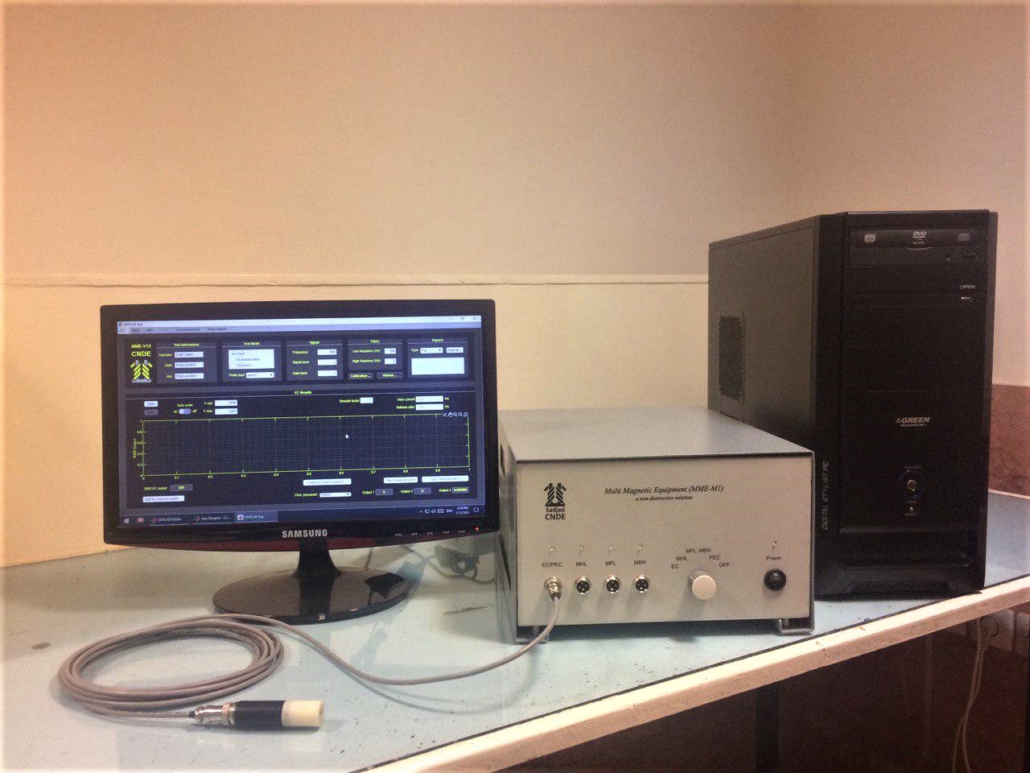

Non-destructive inspection probes

Our Team

Dr. Iman Ahadi Akhlaghi

Dr. Saeed Kahrobaee

Prof. Ali Haerian Ardakani

Mr. Farzad Akhlaghi

Mr. Hossein Norouzi